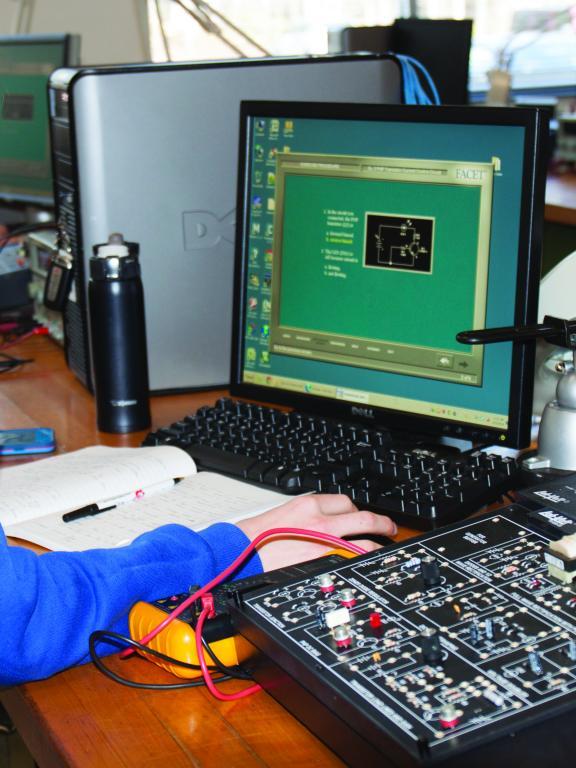

In our Mechatronics Engineering Technology diploma program, you will gain knowledge and hands-on training for the in-demand field of mechatronics, which combines electronics, robotics, mechanics, instrumentation, process control, and industrial automation. Coursework includes computer-aided drafting and design, applied mechanics, materials engineering, quality control, manufacturing methods and processes, computer usage, mathematics, physics, and oral and written communications. The courses will stress critical thinking, planning, and problem solving.

This is a diploma program and requires fewer credits and less time to complete than a degree program. If you’re looking for an even quicker option, the certificate program may be for you.

The Mechatronics Engineering Technology program also offers degree and certificate options.

Skills You’ll Learn

The Mechatronics Engineering Technology program is focused on job-related skills in the following areas:

- Mastering industrial maintenance

- Maintaining, troubleshooting, and repairing industrial systems

- Maintaining a safe work environment while communicating effectively and demonstrating employability skills in the workplace

Career Opportunities

There are many employment opportunities for Mechatronics Engineering Technology graduates, including:

- Engineering technicians

- Industrial technicians

- Industrial technology managers

- Maintenance technicians

- Process improvement technicians

- Technical service providers

Plan of Study

The recommended course sequence for this program and a complete list of related classes are available in the Academic Catalog. Click the button below to view a copy of this plan of study, which is also available as a PDF.